Hi-CON Technocast: Your Business Partner Forever

Hi-CON Technocast Pvt. Ltd. is a long-term partner for investment casting and finished components, using advanced technology, modern facilities, and proven methods to deliver them with quality, consistency, on-time deliveries, and competitive prices. Since 2003, the company has evolved from a foundry into a comprehensive manufacturing solution provider, offering one-stop supplies of duly machined and treated, ready-to-use investment castings and sub-assemblies.

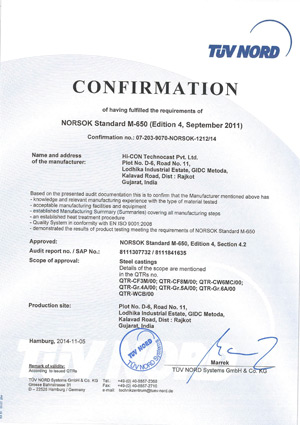

Hi-CON Technocast is well-known brand in Investment Casting Industries & highly recognized as leading investment casting manufacturer, supplier & exporter in India.

Investment Casting Manufacturer in India

Unbiased engineering consultation supports design for casting, material optimization, and selection of suitable manufacturing routes to achieve tight tolerances, complex geometries, and excellent surface finishes. Capabilities span stainless steel, carbon steel, and special alloys to meet demanding application requirements across diverse industries.

Located at India's largest technical and industrial hub in Rajkot, Gujarat, multiple manufacturing facilities produce 4,200 MT of metal castings per year while expanding into assembled items and complete component solutions. A 750+ skilled workforce and robust process controls enable repeatable performance, precision surface finish, and dimensional accuracy from sampling through serial production.

Read MoreInvestment Casting Supplier & Exporter in India

Our manufacturing brilliance has positioned our organization as a recognized Three Star Export House, reflecting approximately 70% export business and consistent delivery performance in international markets. Investment casting products and ready-to-use components are supplied with dependable quality to 22+ countries including the USA, Germany, Denmark, UK, France, Italy, Portugal, China, and the UAE.

When industrial pump programs demand high-efficiency components, when automotive leaders require zero-defect consistency, and when offshore platforms target years of service life, certified processes provide confidence where failure is not an option. End-to-end accountability streamlines procurement and reduces risk across the full lifecycle.

Sustainability leadership creates competitive advantage: 5 MW renewable energy capacity generates up to 84% green power of total energy usage, while active monitoring systems track and optimize our natural resource usage and reduce waste through innovative manufacturing processes. This commitment aligns performance, cost, health, safety, environmental stewardship, and sustainable production without compromise.

The future of manufacturing at Hi-CON is powered by Advanced Engineering & Simulation technology, rapid pattern routes, robotic automation, and continuous improvement—transforming engineering challenges into manufacturing solutions that de-risk programs and reduce total cost of ownership. Start a project or request a DFM review to accelerate development with transparent lead times and reliable delivery.

Grade wise Production

Carbon Steel15%

Stainless Steel25%

Duplex & Super Duplex Steel20%

Nickel Based Alloy35%

Others05%

latest blog

We take this opportunity in announcing the development of 4” #2500 Ball Valve Body w...

There’s a beautiful quote by Lakeisha M. Williams“A true leader never stops being a stud...

As part of our overall commitment for quality, delivery and support to the customer, our customer re...